Quality assurance in medical components

CHRocodile optical sensors

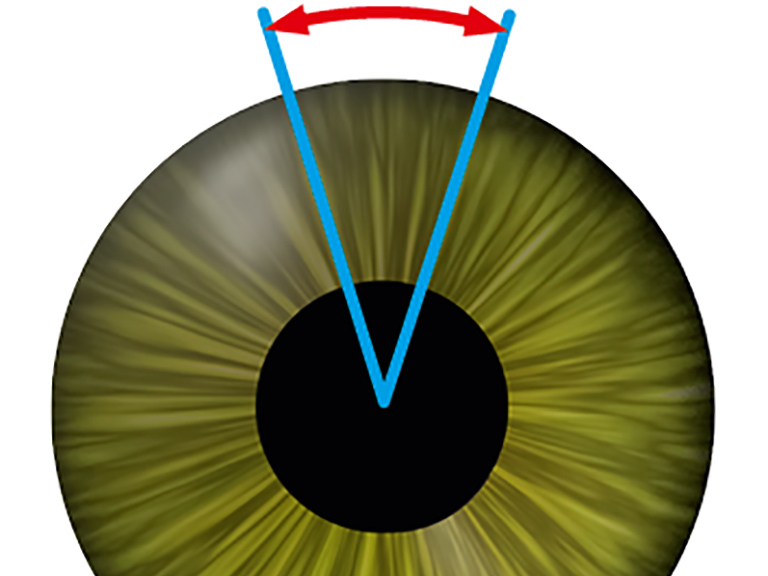

The exact wall strength of medical balloons is critical for the success of therapy. The highest possible precision is vital when processing spectacle glass and contact lenses. Precisely compensating for eye movement is vital during refractive eye surgery. These three examples show how important quality control and precise tracking are found in medical technology applications.

Precitec CHRocodile optical sensors deliver high-precision non-contact distance and layer thickness measurements of medical components. With highest precision, they measure the thickness of glass, the anti-scratch coating on glass, blisters, molds and lenses, as well as artificial joints and stents.

Precitec EyeTracker provides the prerequisite for successful refractive eye surgery with fast eye tracking in up to six dimensions. All Precitec EyeTracker are certified according to ISO 13485 / ISO 9001, and thus meet the strict quality requirements of the medical industry.

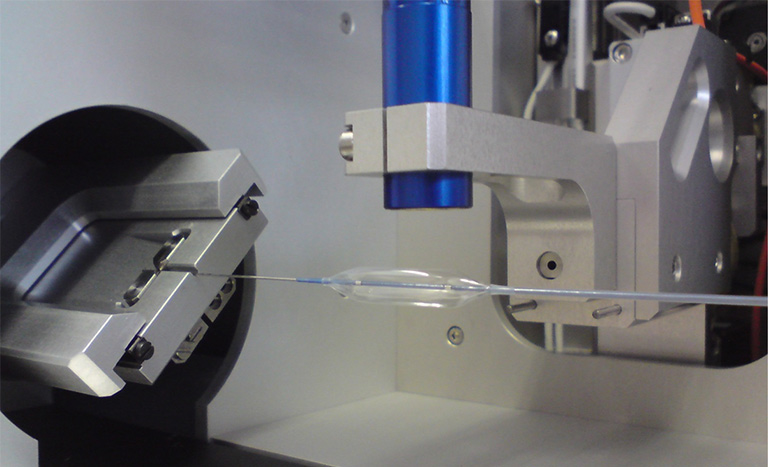

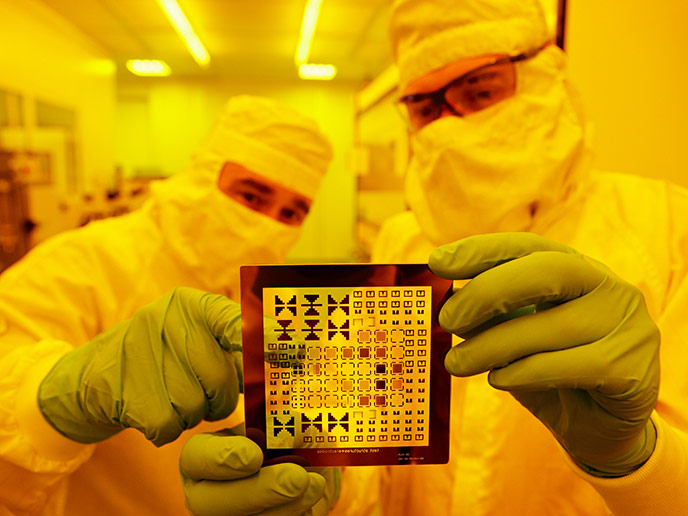

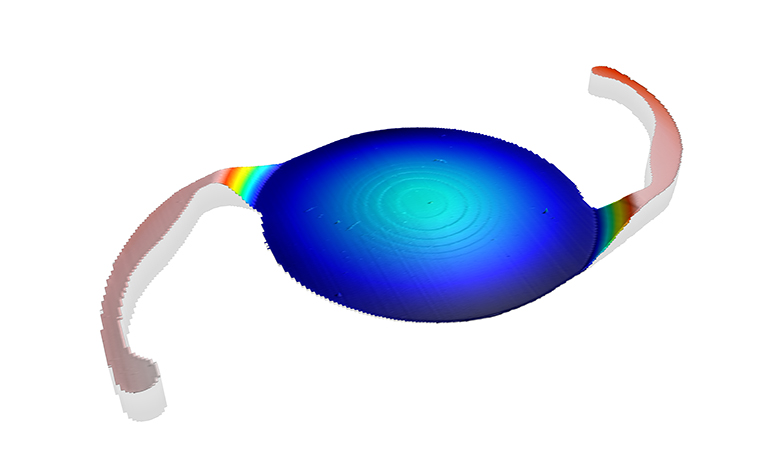

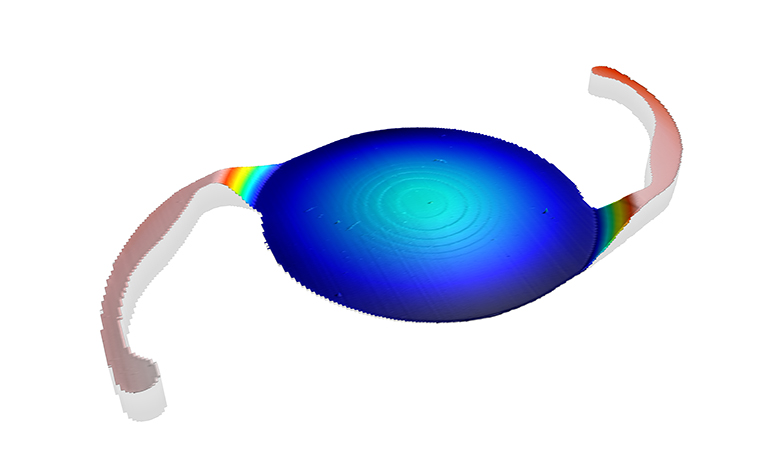

Inspecting the thickness of IOLs and lenses

Intraocular lenses (IOLs) are placed inside the human eye, contact lenses on the surface of the eye. In both cases, the curvature and thickness of the lenses determine their refractive effects, and are thus crucial to their effectiveness.

Precitecs CHRocodile CLS line confocal sensor is well suited to measuring the center thickness of a lens and its curvature.

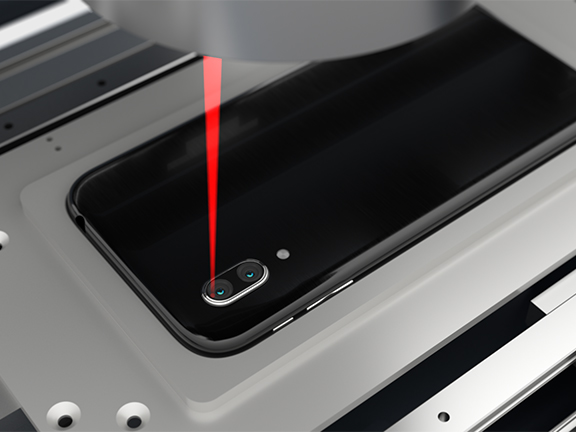

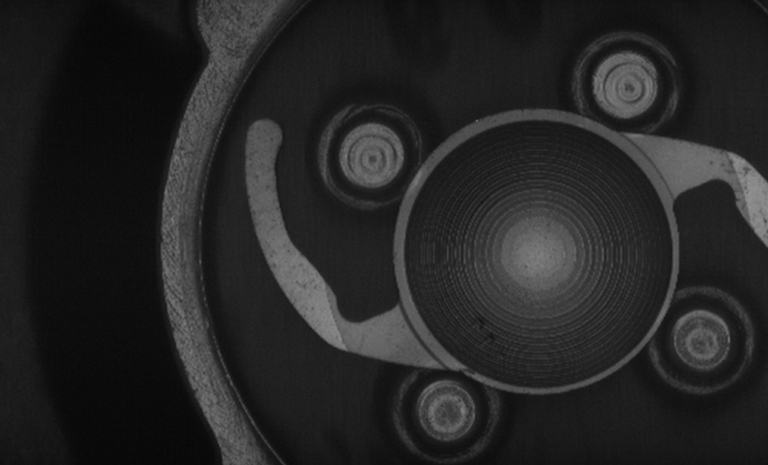

Detecting defects on IOLs and contact lenses

A key quality criterion for IOLs and contact lenses is that they need to be free of scratches or other defects which are not visible to the human eye, but will cause problems if they go undetected before implantation.

The Precitec Chromatic Vision Camera (CVC) is well suited to quickly and reliably detect any scratches or other defects, as well as controlling the diameter of a lens and the dimensions of IOL features.

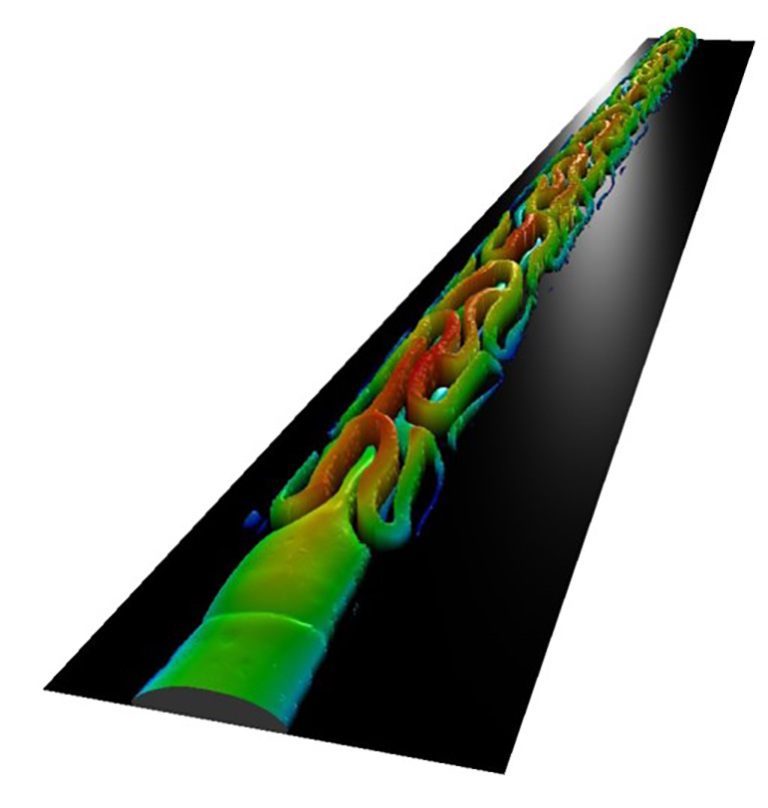

Comprehensive inspection of stents

The stents placed in blood vessels need to be subject to dimension and strut inspections. The complex geometry and structure of the stent is a challenge to other sensor systems.

However the CHRocodile CLS confocal line sensor can carry out a comprehensive inspection of all these parameters by quickly measuring the full surface of the stent.

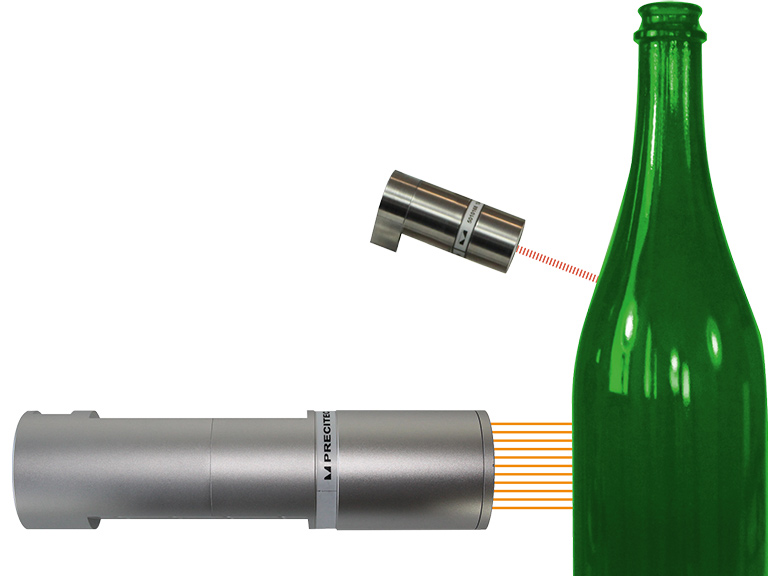

Measuring the wall thickness of balloons

The material used for medical balloons is a milky, opaque plastic with a thickness of only 50-150 µm. The medical industry's strict requirements demand a high degree of accuracy in such thickness measurements, which cannot be performed by means of chromatic confocal technology.

The CHRocodile IT series is the perfect fit for this challenging task. A cost efficient solution is the CHRocodile 2 S, which can be switched from chromatic to interferometric mode, making it a suitable sensor for semi-transparent balloons.