The automotive industry is passing through disruptive times, with e-mobility being just one of the trendsetting catchwords. At Precitec we have the state-of-the-art optical technologies that the automotive industry needs to stay one step ahead of such disruptive changes. The applications for which our non-contact optical technologies offer solutions for automotive metrology.

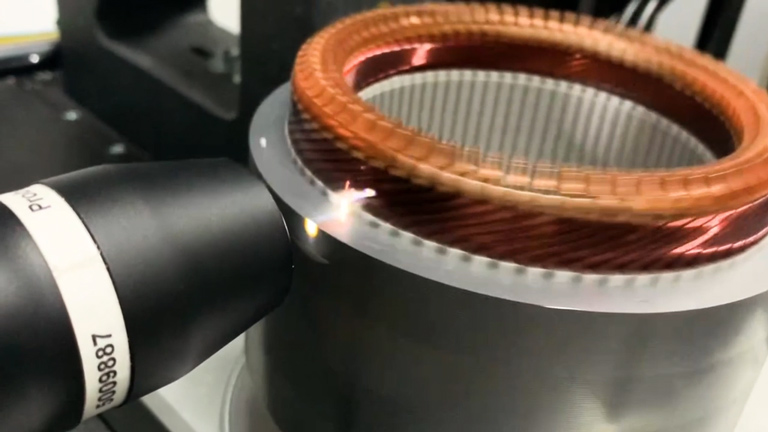

A contribution to e-mobility and an important component for the quality control of hair pins is the thickness measurement of the insulation layer on copper hair pins. Manufacturers and suppliers in the automotive industry have a competitive advantage in the area of production quality, among other things, due to the products from the line sensor series - line sensor CHRocodile CLS 2Pro, line sensor CHRocodile CLS 2 or line sensor CHRocodile CLS HS.

Lamellar zinc paint protects automotive brake disc from corrosion. Controlling the thickness of the paint is essential to ensure its durability. Existing contact or radiative measurement technologies have their limitations, whereas the non-contact, non-destructive, non-intrusive and fast laser photothermal technology from Enovasense offers numerous benefits, such as outstanding repeatability, precision, cost effectiveness, and easy integrability into a production process.

Detailed information can be downloaded by filling out the form.

Diode laser-based hard coatings have been shown to reduce PM10 brake dust by up to 90% and fully comply with the new Euro 7 vehicle emission standard applicable from 2025. Precisely controlling the thickness of these laser cladding layers is vital to ensure enough hard material covers the entire brake disc track.

Whereas existing measurement technologies are unsuitable for this task, Precitec Enovasense’s laser photothermal technology is the ideal solution, offering outstanding repeatability and precision in high-resolution coating thickness scanning.

Detailed information can be obtained by filling out the form.