Laser remote welding for series production

Remote welding or scanner welding stands for highly dynamic and economical laser welding. This involves working with large focal lengths that give a great operating range. The laser beam is directed onto fast-moving deflection mirrors and then onto the workpiece. There is no need to move the processing unit or the workpiece. This results in a processing field in which welding is performed quickly with high precision. Non-productive times are almost completely eliminated by the highly dynamic movements, and reproducibility is increased.

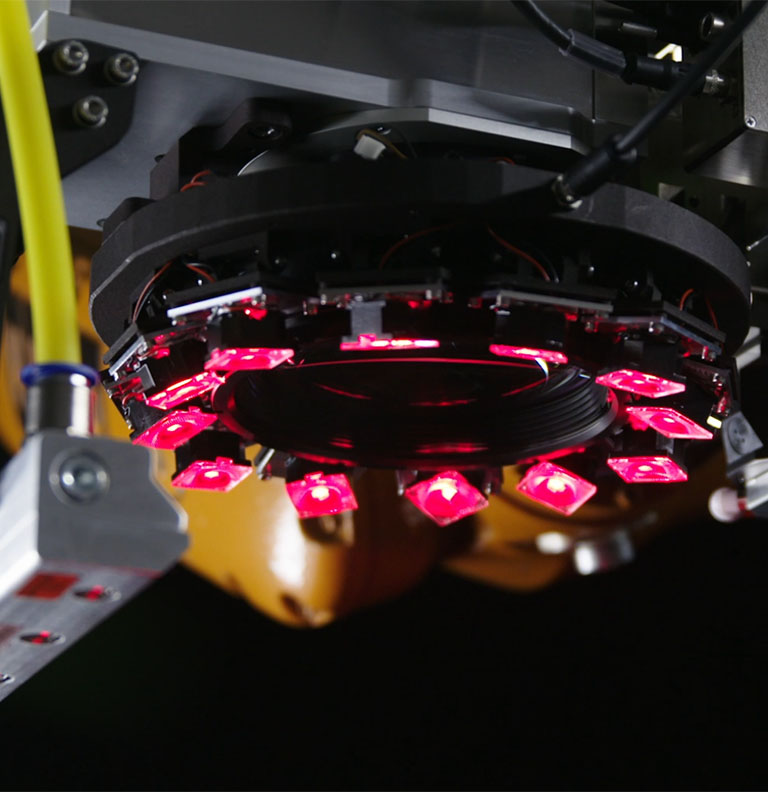

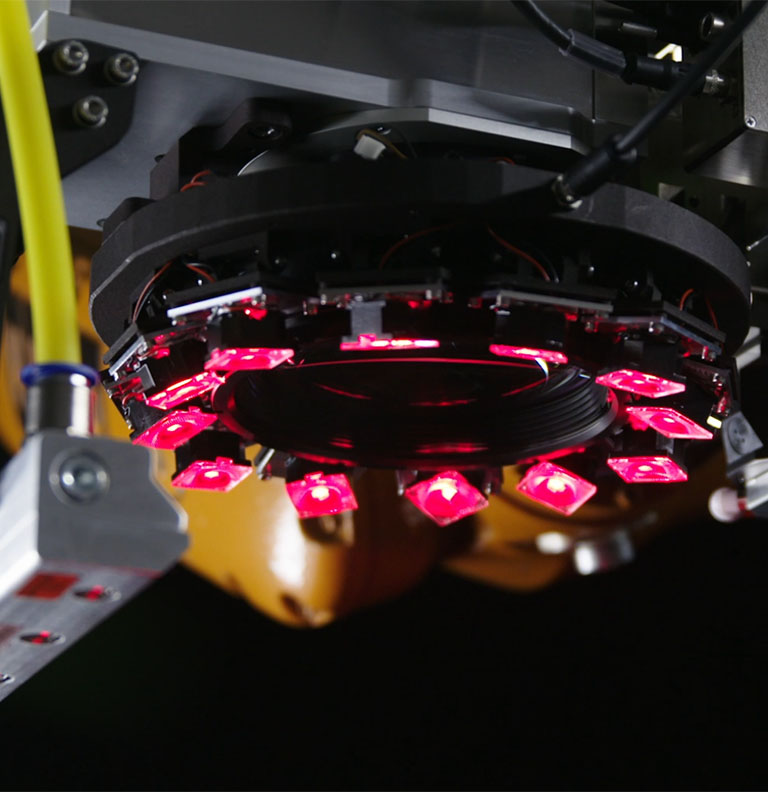

Precitec offers various laser remote systems: from 1D solutions to extensive 2.5D scanner processing systems. The ScanWelder enables targeted use of laser power in width and depth. This results in optimized weld seams, especially in aluminum welding. Electrical conductivity and tightness are important criteria in e-mobility. Here, the ScanMaster represents a total solution consisting of distance measurement, component position detection and process monitoring for use in highly dynamic battery series production.

Highly productive scanner welding

- Remote processing for precise, reproducible production

- Stable process with component recognition and autofocus

- Increased process reliability through intelligent process monitoring and control

Remote laser welding of Aluminium

- Cost-efficient laser welding without filler wire

- Optimized welding seams through targeted application of the laser power

- Increase of the process stability

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/Home/laser-welding/UEberwachung_Ressource_768x576.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/Home/laser-welding/Koepfe_Ressource_768x576_01.jpg)