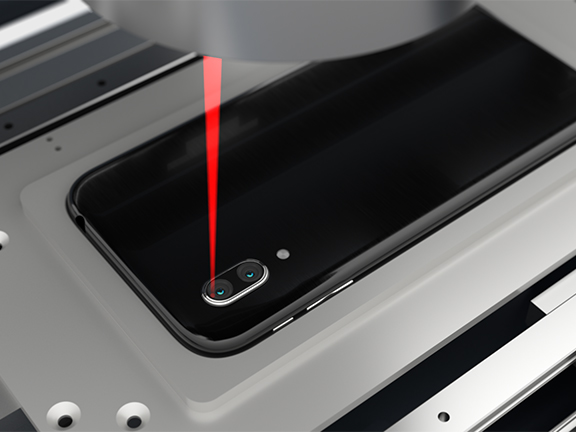

Inline wall thickness measurement of glass

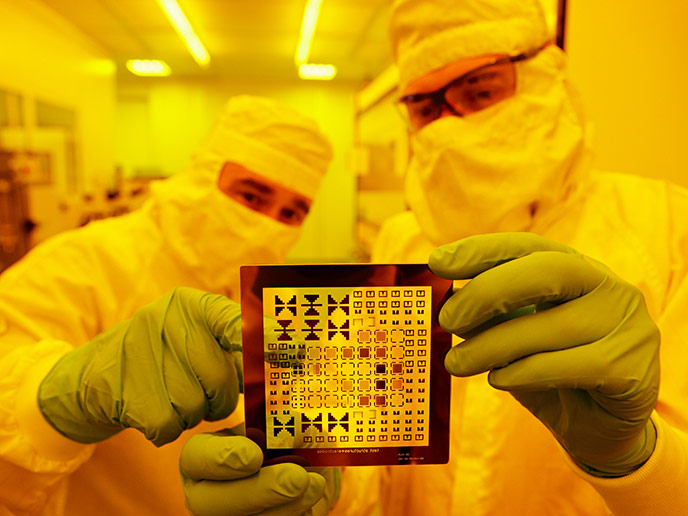

CHRocodile sensor family

CHRocodile sensors measure the thickness and topography of glass of any color or surface structure in multifaceted application areas. These sensors have become the industry standard in wall thickness measurement of glass containers in inspection machines, as well as gauge measurement of display glass and pipe glass.

Circular deviations of bottles, the wall strength of hot quartz pipes, or function foil in pre-fabricated sandwiched layers, can be easily determined. And even at glass temperatures of 1,700 °C the sensor does not get too hot.

Measuring the wall thickness and topography of glass bottles

The wall thickness of every single glass bottle has to be checked to avoid breakage and possible harm to the user. Such sensors have to be robust, compact, accurate, and have to work in harsh industrial environments.

Inline CHRocodile MPS multipoint sensors measure – even at the hot end – geometries, shape and wall thickness on various parts of the containers.

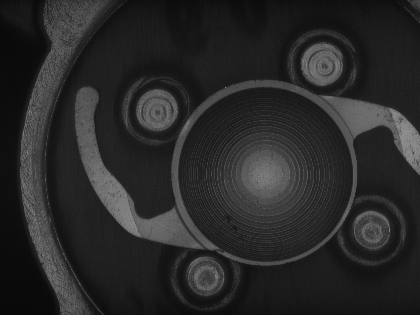

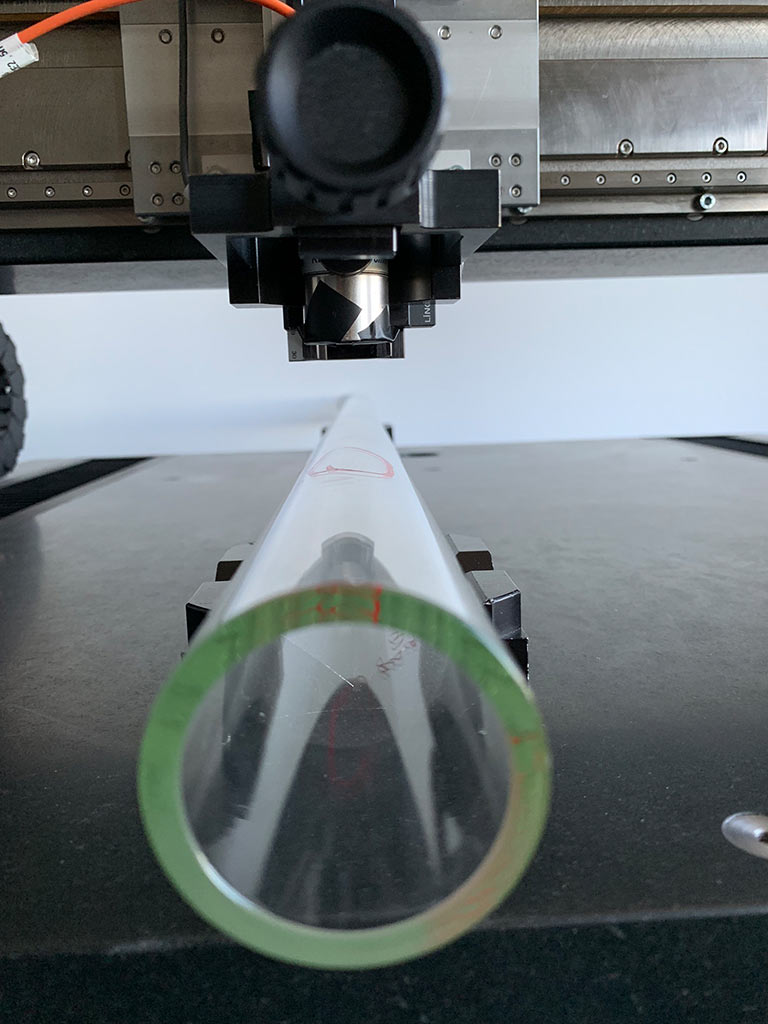

Measuring the wall thickness and roundness of tubing glass

Glass tubes are used in medical industry for the production of vials, ampoules and syringes. The wall thickness has to be controlled very precisely, in view of the strict quality control and regulations in medical industry.

In inline and offline inspection environments the CHRocodile 2 IT measures the wall thickness and roundness of tubes accurately and quickly in both cold end and hot end production.

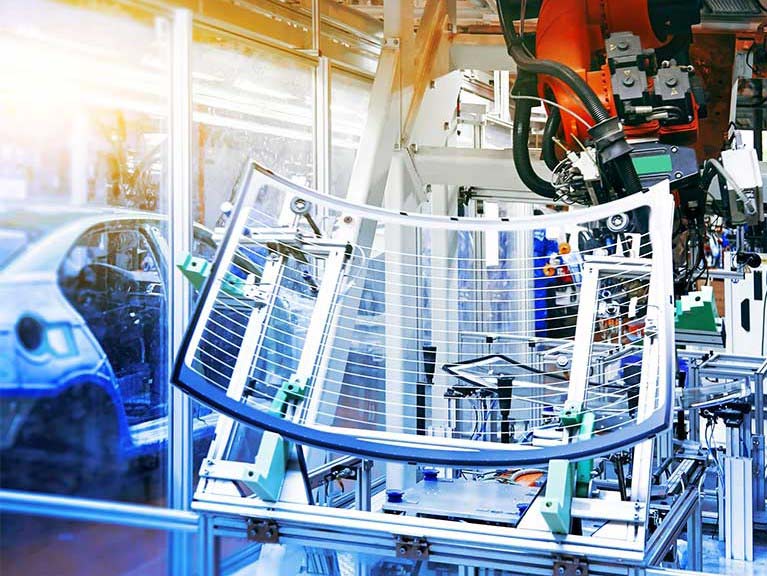

Measuring the thickness of flat glass inline

Production of the CERAN®- and TFT-glass requires accurate measurement of the thickness and waviness of hot glass during production. By using CHRocodile MPS sensors, it is possible to carry out inline thickness measurements.

At the same time thickness determination of hot glass as well as waviness, inspections can be performed. The robust optical probes and durable controller are ideally suited for applications in a harsh industrial environment.

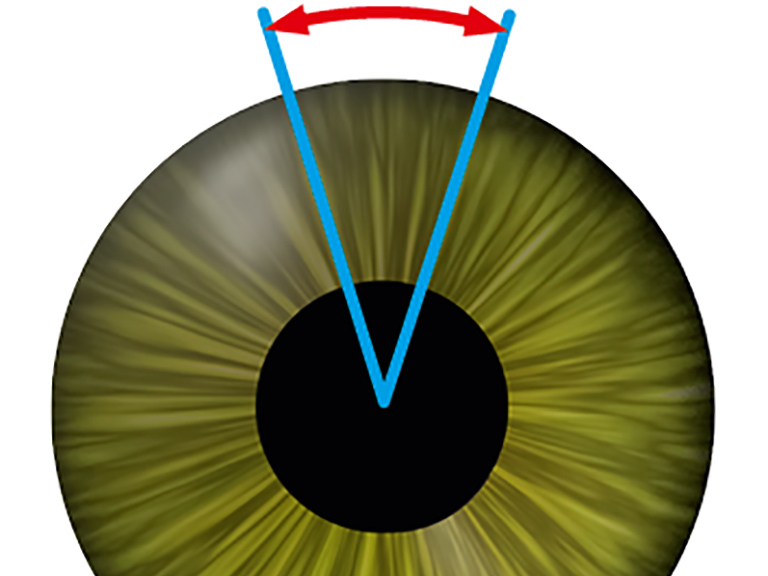

Measuring the geometry of small medical glass containers

Measuring the crimp neck thickness, profile and opening diameter of small glass containers for medical purposes is challenging as the bottle opening is small and only one-sided measurement is possible.

Despite the challenging geometry of such containers, the CHRocodile 2 DPS is the ideal solution since it measures the thickness of the crimp neck and the inside and outside profiles via the distance data. The whole circumference can be scanned and the opening diameter determined from the inside distance data. Finally, the bow and wall thickness of a container can be measured.