Ultra-precise thickness and distance measurement

How interferometry works

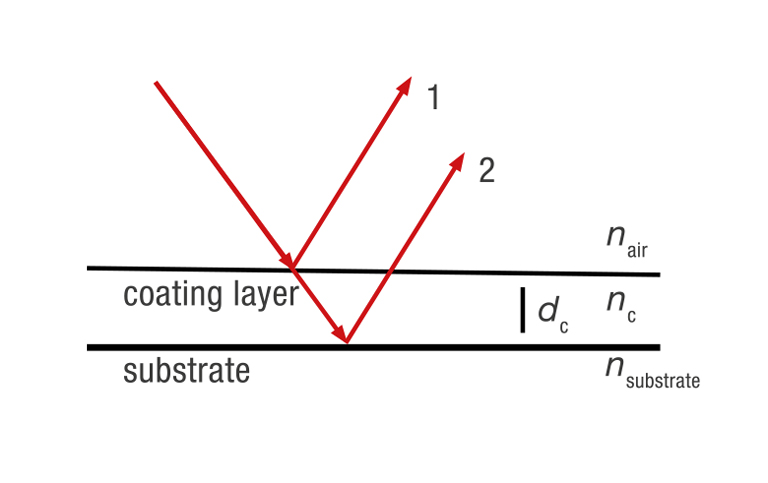

Interferometers make use of the effects that occur when two or more beams of the same light source with slightly different path lengths are superimposed.

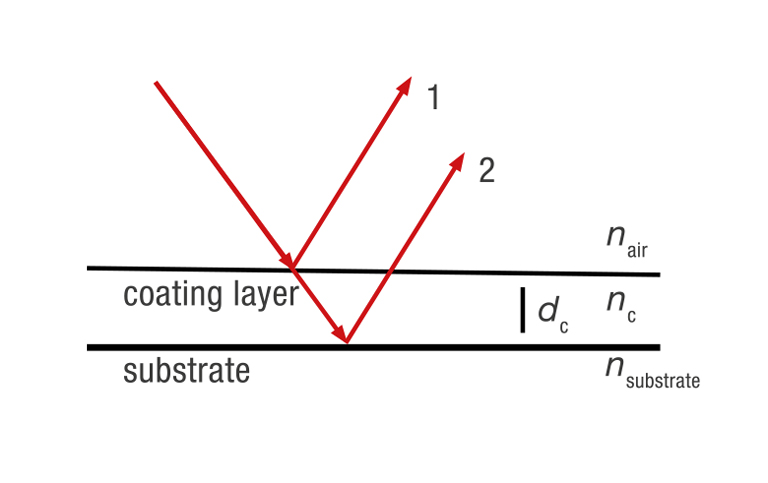

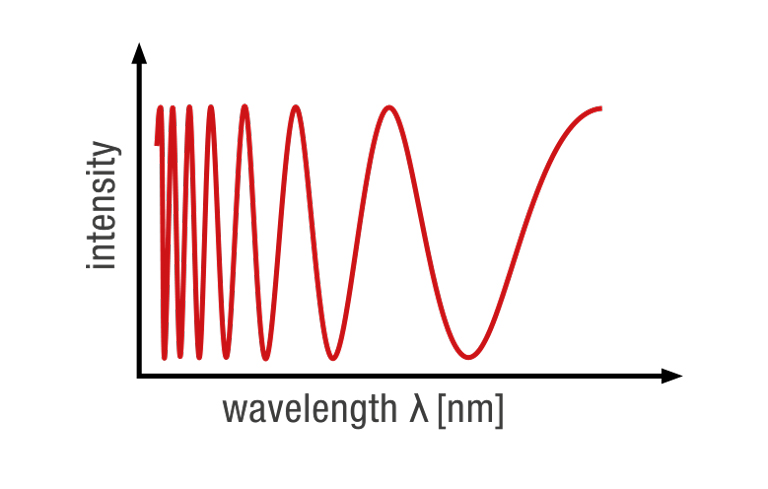

The resulting spectrum and its modulation frequency contain the distance or layer thickness data, depending on the measuring task the system is applied to.

By calculating the Fourier transformation of the spectrum, it is possible to determine measurements at speeds up to 70 kHz.

Interferometry is ideally suited to large-area measurements as the accuracy of the measurement is not dependent on the distance to the object.

Advantages of interferometric sensors

- High-speed inline inspections at up to 70 kHz

- Insensitive to heat, humidity or vibration and thus suitable for harsh industrial environments, even in liquids such as water, oil or acids

- Suitable for quality assurance, surface and thickness measurement

- Unique optical technology capable of measuring multi-layer laminated glass

- Ultra-precise thickness measurements from 0.6 - 15,000 µm

- Thickness measurement of all infrared-transparent materials, e.g. in wafer inspection processes

- Static or moving measuring spot

- Passive optical probes – compact and passive, no wear and tear

For more information on how you can benefit from our interferometric sensors view our product detail pages.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/Home/3d-messtechnik/technology/Chromatic_Confocal_Principle_Precitec-Optronik_Linking.jpg)