Precision and efficiency for e-mobility - Shape the future with innovative technologies

The mobility world is currently changing rapidly. Everyone is talking about e-mobility and e-car manufacturers are reporting record deliveries. Against this backdrop and sustainable and resource-saving mobility, the focus is on innovative manufacturing methods for batteries and battery modules, fuel cells as well as e-motors and power electronics.

In this growing market, Precitec is setting key impulses together with its customers: in the field of laser technology and 3D measurement technology - for the highest quality in production as well as the highest efficiency of manufacturing plants.

Fuel cell

A fuel cell consists of numerous bipolar plates that have to be welded gas-tight. In most cases, the welding speeds are very high - as are the quality requirements for the weld seam. In addition, the geometric parameters of the bipolar plates must be precisely maintained to ensure high fuel cell performance. We measure these with our 3D measurement technology sensors.

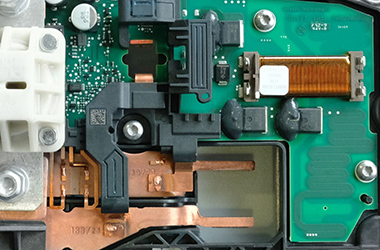

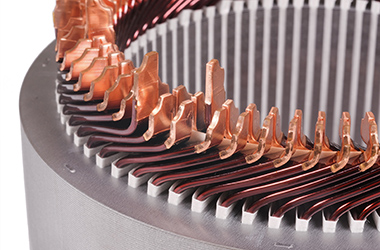

Powertrain

The electric drive strand consists of the stator, rotor and power electronics, among other things. For high-quality laser welding of stators (hairpin welding), well-stripped hairpin wires are crucial. We can detect varnish residues on wires as well as enable adaptive laser welding processes.

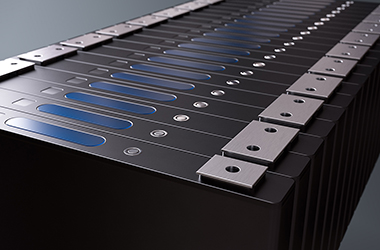

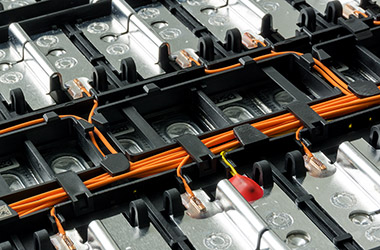

Your global partner for battery manufacturing

Benefit from our solutions along the entire production process in the field of e-mobility: From thickness measurement of copper foils, laser welding of foil-to-tab or cap-to-can as well as quality control of battery cells and modules, to laser welding of terminal contacts or hairpins.