Intelligent distance control during laser cutting processes

The CutBox Pro platform combines previous Precitec distance sensor functionalities into a single hardware. In addition, the CutBox Pro offers modern functionalities such as our newest feature - BeamTec, the real-time adjustment of the focus position - an additional advantage for the productivity of your cutting system.

Advantages

- Real-time monitoring for increased machine availability

The EtherCAT® or ProfiNET® interface enables permanent monitoring of all sensor values in real time. Thanks to the GUI specially developed for the CutBox Pro, you have these sensor values in view at all times and can react quickly to deviations. This leads to increased machine availability and more output.

The GUI offers a wide range of configuration options, such as setting parameters for focus and distance control as well as setting threshold values. Stable processes for your productivity

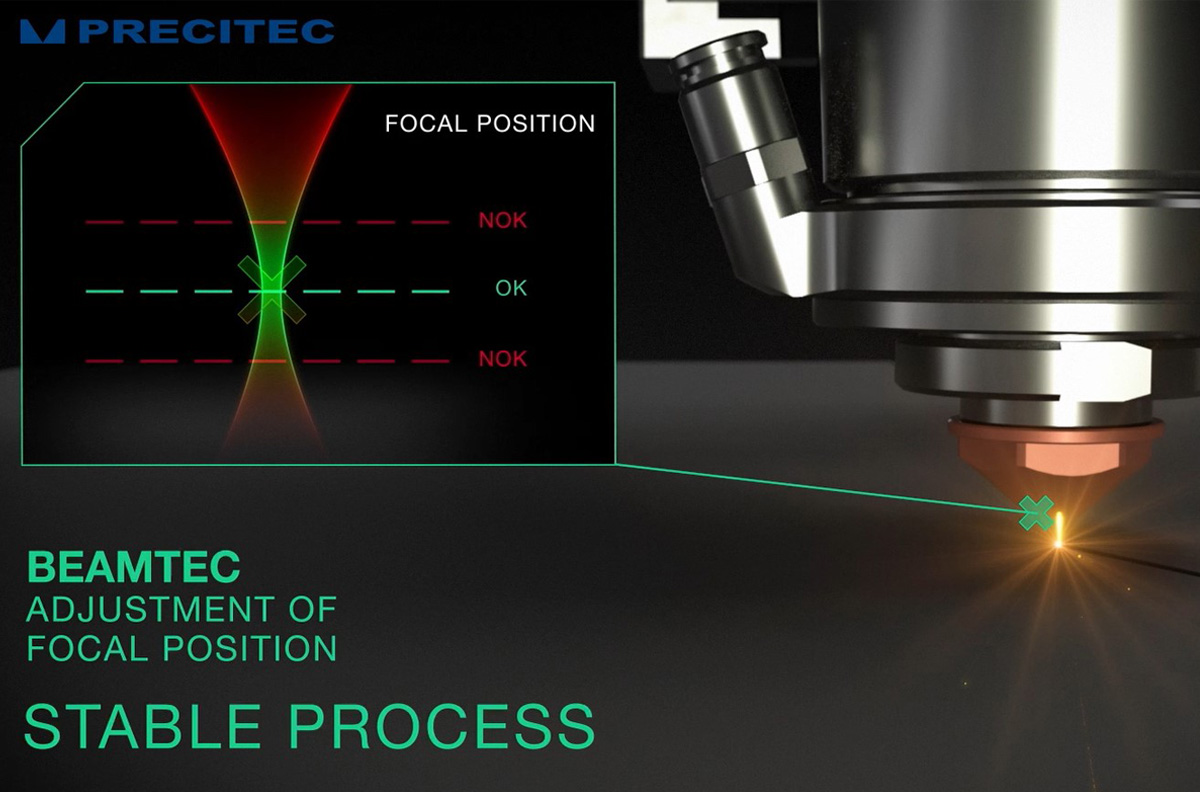

Precitec's precise distance sensor technology still represents the reference in the field of 2D and 3D laser cutting. The CutBox Pro combines previous functionalities in a single hardware. EtherCAT® or ProfiNET® compatibility enables fast communication with reduced cycle times. The advanced real-time adjustment of the focus position optimizes the stability of your cutting process, increasing the productivity of your cutting system.BeamTec: Real-time adjustment of the focus position

The new feature BeamTec increases the stability of the cutting process due to our real-time adjustment of the focus position

Technical data

- Inputs: 2x analog (0..10 V)

- Outputs: 2x analog (out 1: 0.. 10 V, out 2: -10.. 10V)

- Fieldbus interfaces: EtherCAT®- or ProfiNET®

- Measuring range: 0.1 - 30 mm

- Cycle time: 1 ms

We need your consent to load the form!

We use Marketing Cloud Account Engagement (Pardot) Forms to embed content that may collect data about your activity. Please review the details and click in the Pardot box to accept the service and see the content. If the form is not displayed correctly, please click once more on Download the data sheet now.

Our service for your productivity

Maintenance Laser Technology

Learn more

Commissioning Laser Technology

Learn more

Repair Laser Technology

Learn more

Spare Parts Laser Technology

Learn more

Hotline Laser Technology

Learn more

Training Laser Technology

Learn more