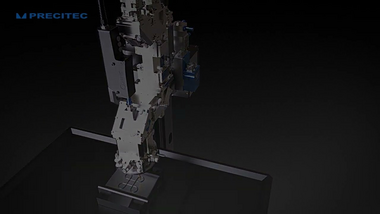

Highly accurate detection of surface defects and reliable evaluation

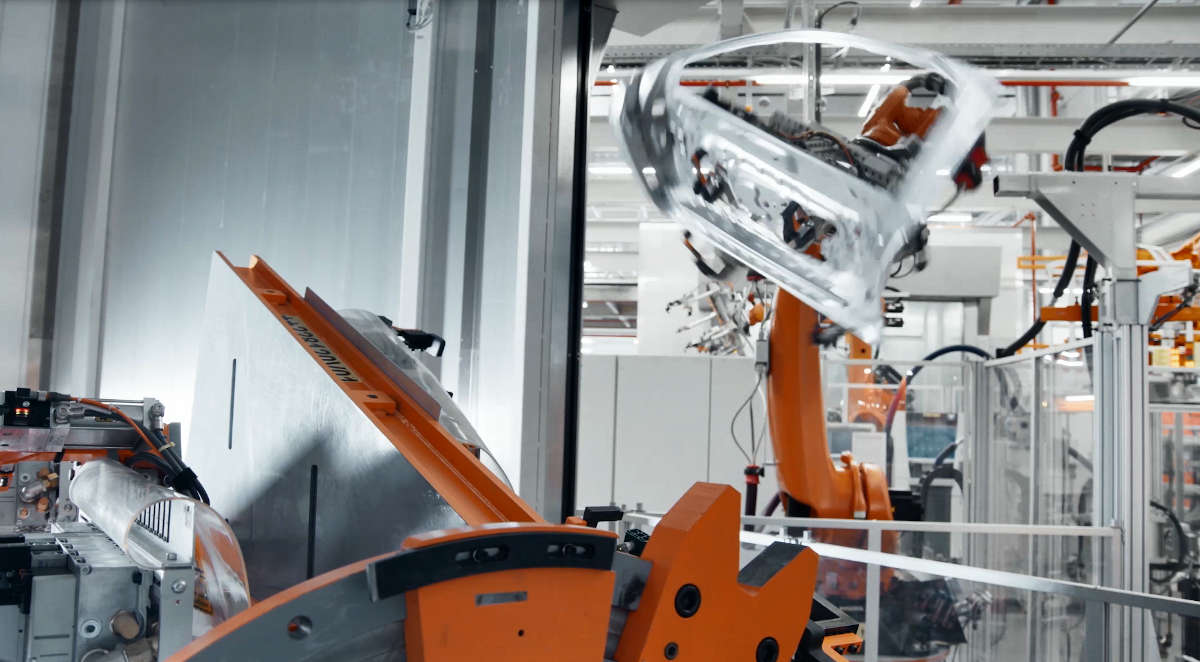

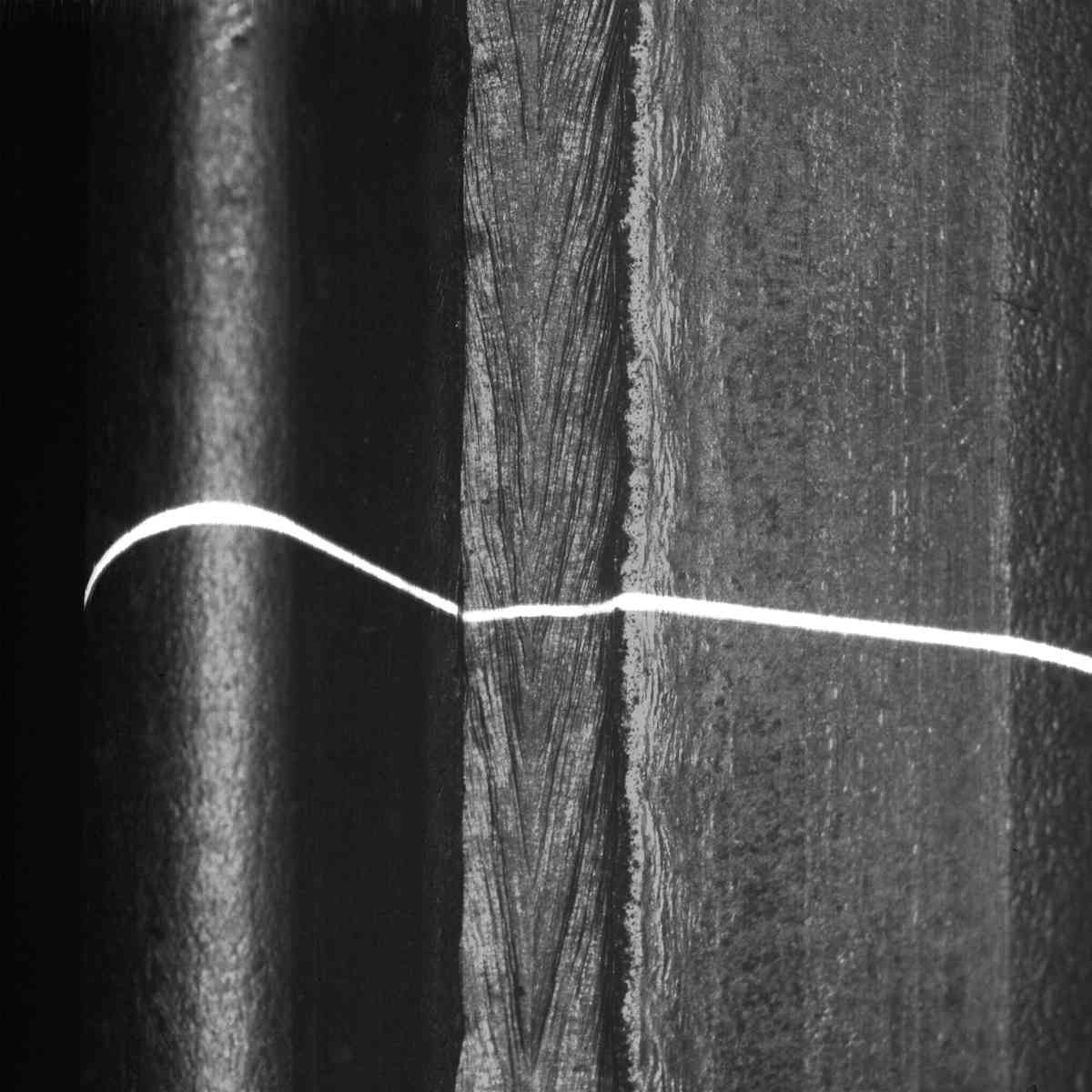

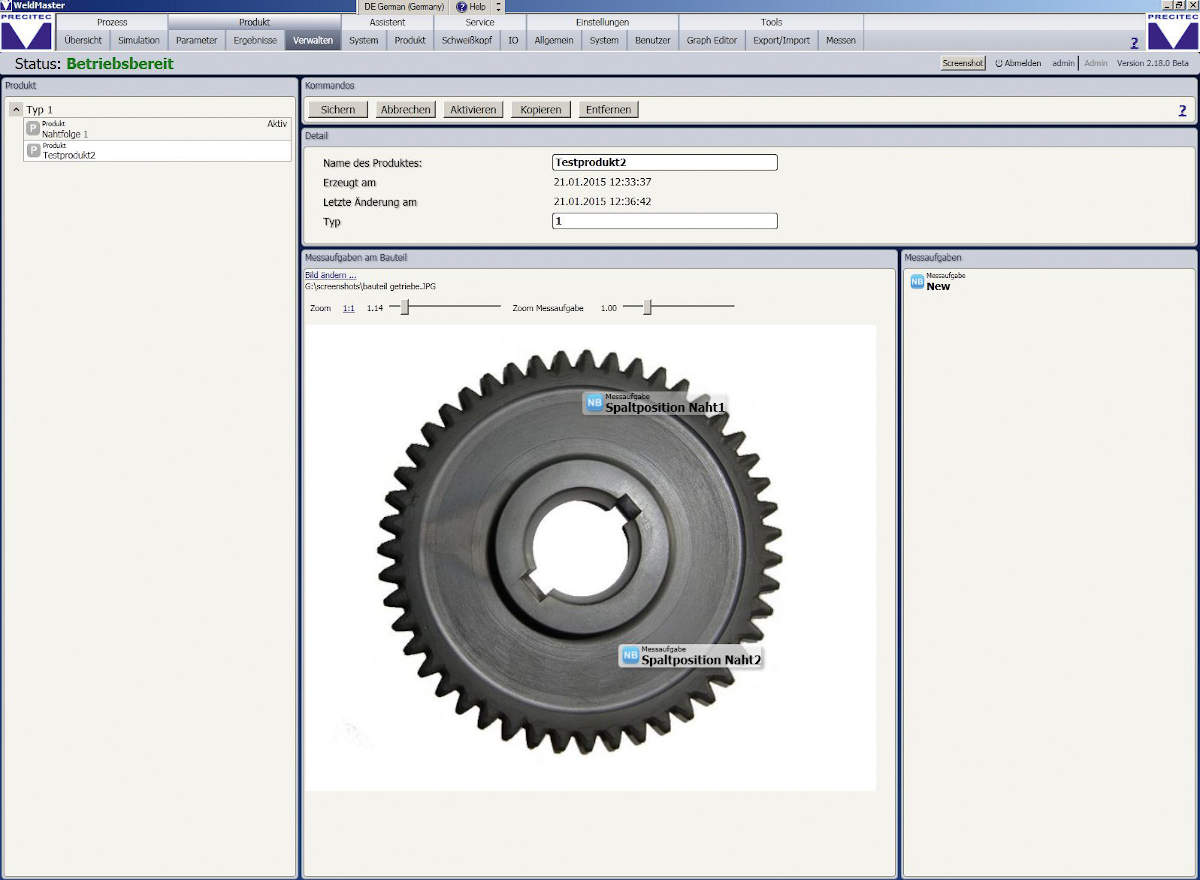

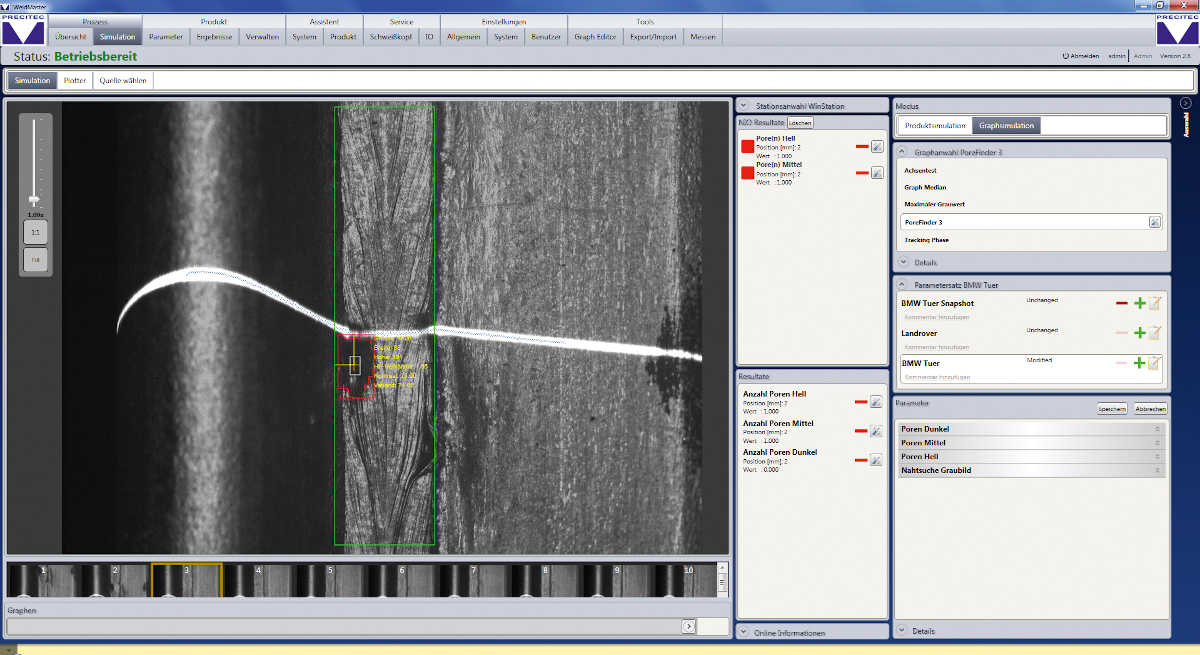

The WeldMaster 4.0 Inspect can work independently of the actual welding station. It is a self-sufficient quality control system that detects surface defects with high precision and evaluates them reliably. Components with smallest gaps, holes, cracks and other surface defects are rejected from the running production. This ensures a smooth production process. The system also recognizes high-resolution seam profiles in 3D form, compares them with a predefined threshold values and classifies them as good or bad parts.

Advantages

- 100% quality control

The WeldMaster 4.0 Inspect is used worldwide as an offline quality system. For almost all seam shapes, you can detect and evaluate many types of defects such as surface defects or holes, gaps, notches as well as weld formations such as convection, seam width, or the general seam geometry. - 100% documentation

The data from the inspection are permanently stored and are available to the user. Even after years, the user can exclusively query and trace back the complete analysis results of the joining seam. By assigning customer and component numbers, 100% traceability is possible.

Technical data

- Self-sufficient system for offline quality monitoring

- Highly accurate detection of surface defects and reliable evaluation

- 100% documentation

- Standard interfaces to Precitec welding heads

- Standard interfaces for remote inspection cells

We need your consent to load the form!

We use Marketing Cloud Account Engagement (Pardot) Forms to embed content that may collect data about your activity. Please review the details and click in the Pardot box to accept the service and see the content. If the form is not displayed correctly, please click once more on Download the data sheet now.

Our service for your productivity

Commissioning Laser Technology

Learn more

Maintenance Laser Technology

Learn more

Training Laser Technology

Learn more

Spare Parts Laser Technology

Learn more

Repair Laser Technology

Learn more

Hotline Laser Technology

Learn more