Inline quality assurance in hairpin welding: machine learning achieves new levels of precision

Quality assurance in the laser welding of stators with hairpin technology is a major challenge due to the large number of welded joints. Until now, X-ray computed tomography (CT) has been considered the most accurate method, but it is not practical for inline inspection in series production.

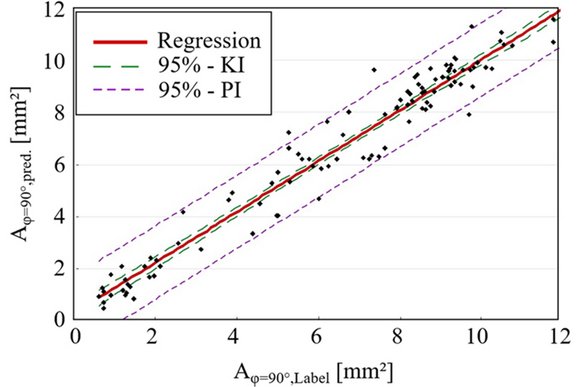

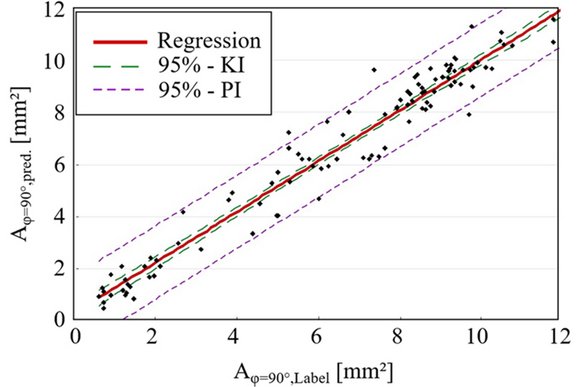

A new method based on machine learning now opens up promising possibilities: By combining various sensor signals - including radiation during the welding process as well as pre- and post-process images - a correlation with the CT measurements of the weld cross-sections is achieved. The developed system achieves a coefficient of determination of 0.953.

In addition, the same data was used to classify the weld seams into six categories with an average accuracy of 98.63%. Both approaches are suitable for series production and show great potential for inline quality assurance in hairpin production. Further improvements are expected through the use of new model architectures and high-resolution cameras.