Publications

Boosting Battery Production with In-Line Measurement

The rising demand for lithium-ion batteries-driven by renewable energy adoption and e-mobility-puts pressure on manufacturers to improve efficiency…

Dr. Markus Kogel-Hollacher is presenting a paper at this year´s Photonics West

Precitec Optronik Head of R&D and Photonics 100 honouree Dr. Markus Kogel-Hollacher is presenting a paper at this year's Photonics West.

He talked…

Why do laser processes play such a vital role in the development of the e-mobility?

Photonics, particularly lasers and sensors, are poised to assume a significant role in the battery market in the upcoming years. The evolution of…

![[Translate to Englisch:] [Translate to Englisch:] Wire bonding inspection with CHRocodile CLS 2](/fileadmin/user_upload/wire_bonding_inspection_with_CHRocodile-CLS_2_1920x1280px.jpg)

Challenges Wire Bond Inspection

The article from Semi Engineering explores challenges in the wire bonding industry as seen by key players in the markets. Interesting insights and…

And the Prism Award 2023 goes to..

Precitec 3D Metrology wins prestigious Prism Award 2023.

SPIE, the international society for optics and photonics, honored the Flying Spot Scanner…

![[Translate to Englisch:] Enovasense sensor at work](/fileadmin/News/Enovasense_Sensor_1920x1280.jpg)

Precitec Acquires Majority Stake in Enovasense Thickness Sensor Company

Precitec Optronik has acquired a majority stake in the French start-up Enovasense with its technology to measure the thickness of all kinds of…

![[Translate to Englisch:] Nominees for Test and Measurement category](/fileadmin/News/Prism_Award_2023_1920x1280.jpg)

Precitec 3D Metrology is nominated for SPIE Prism Award

SPIE announces finalists for 2023 Prism Awards

The annual awards celebrate the best of photonics innovation in areas such as biomedical devices,…

Hand in hand for customised solutions

Article in Glass WorldWide April 2021

Precitec’s optical measuring technology is used throughout manufacturing industry for quality inspection and…

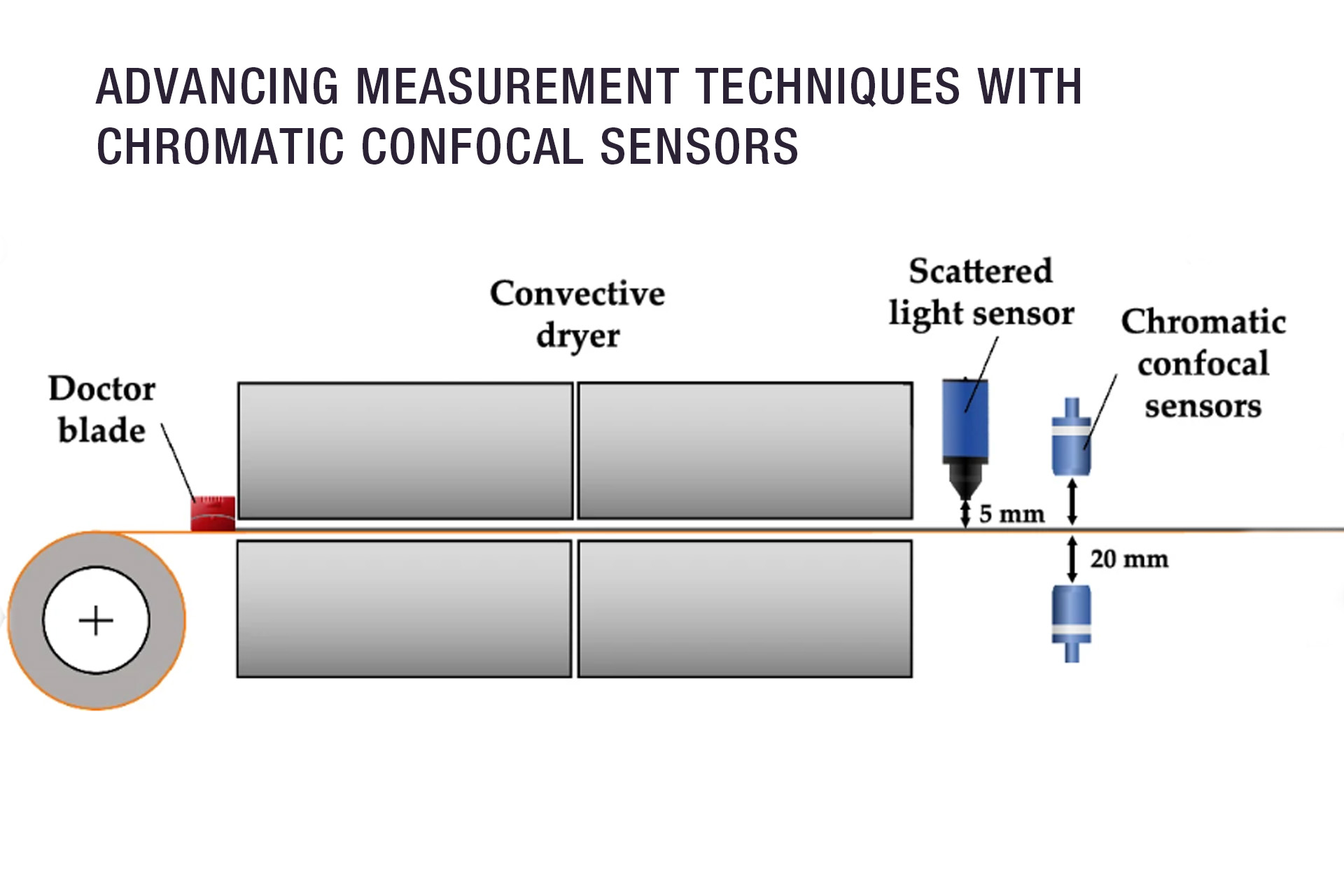

Non-contact thickness measurement of non-transparent components

Publication in the German Magazine InVision in April 2020

With the CHRocodile 2 DPS dual-channel sensor Precitec Optronik offers a stand-alone…

![[Translate to Englisch:] Anzeige Boss Magazine Flying Spot Scanner](/fileadmin/fileadmin/publications-de/Precitec-Anzeige-Boss-7.75x4.jpg)