Publications

![[Translate to Englisch:] Enovasense sensor at work](/fileadmin/News/Enovasense_Sensor_1920x1280.jpg)

Precitec Acquires Majority Stake in Enovasense Thickness Sensor Company

Precitec Optronik has acquired a majority stake in the French start-up Enovasense with its technology to measure the thickness of all kinds of…

![[Translate to Englisch:] Laser welding systems help to more innovation](/fileadmin/News/Laser_Welding_solutions_for_Emobility_1920x1280.jpg)

Precitec Sees a Bright Future in Laser Welding Systems

"At Precitec, innovation is key" so Klaus Loeffler, Managing Director & Chief Sales Officer at Precitec. To widen the technology, promoting such…

What is the correlation between laser power and productivity?

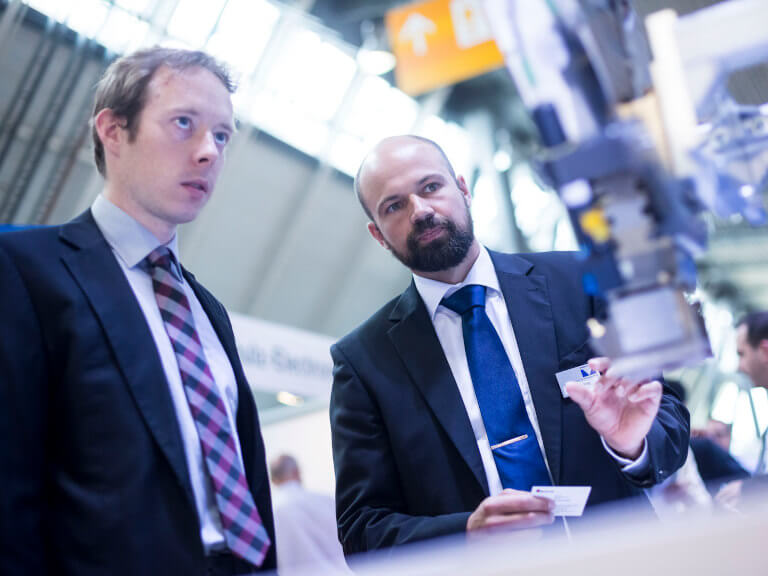

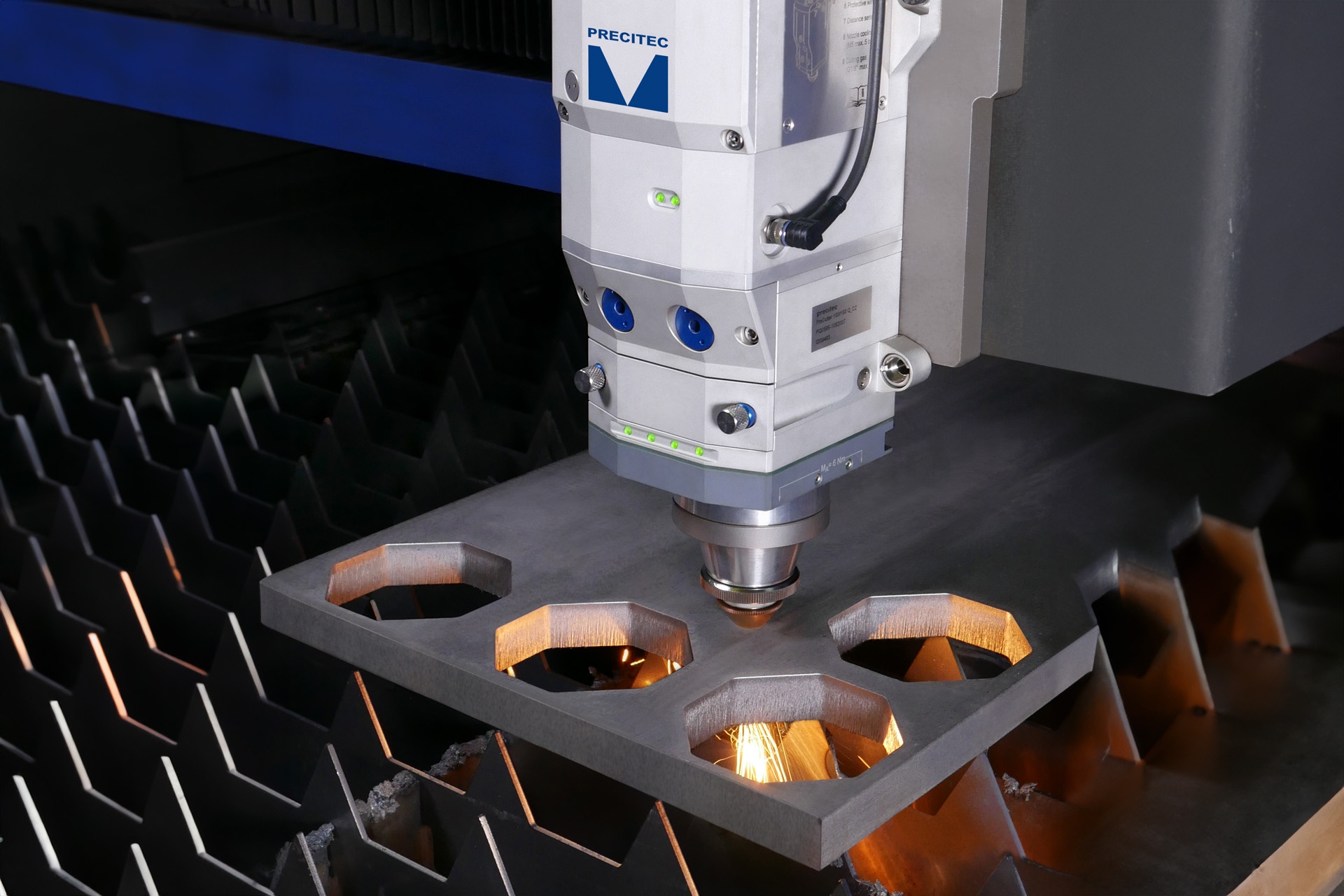

Dr. Markus Kogel-Hollacher speaks about laser cutting heads in the power range of 30kW. The almost linear dependence of laser power and productivity…

What are the benefits of high power laser cutting?

Precitec was one of the company at Euroblech in Hanover, Germany, who offers cutting heads with ultra-high cutting powers. The firm was showcasing its…

![[Translate to Englisch:] Nominees for Test and Measurement category](/fileadmin/News/Prism_Award_2023_1920x1280.jpg)

Precitec 3D Metrology is nominated for SPIE Prism Award

SPIE announces finalists for 2023 Prism Awards

The annual awards celebrate the best of photonics innovation in areas such as biomedical devices,…

Are there any applications for which AI is not interesting?

Joachim Schwarz talks in Laser World Of Photonics about the technological potential of AI for laser-based production and quality monitoring and how…

Hand in hand for customised solutions

Article in Glass WorldWide April 2021

Precitec’s optical measuring technology is used throughout manufacturing industry for quality inspection and…

Non-contact thickness measurement of non-transparent components

Publication in the German Magazine InVision in April 2020

With the CHRocodile 2 DPS dual-channel sensor Precitec Optronik offers a stand-alone…

In-Process Wafer Step Height Measurement

During the grinding process the wafer thickness needs to be controlled in real time. A non-contact, optical measurement technology is the ideal…

![[Translate to Englisch:] Anzeige Boss Magazine Flying Spot Scanner](/fileadmin/fileadmin/publications-de/Precitec-Anzeige-Boss-7.75x4.jpg)