DIPOOL Project: AI-supported laser cutting

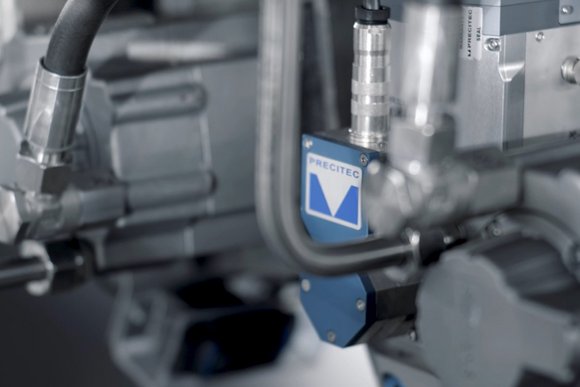

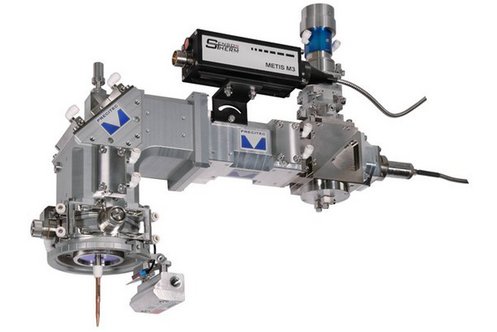

In the DIPOOL - Digital Process Online Optimizer for Intelligent Laser Machines project, Precitec is working with Fraunhofer ILT and other partners to take laser cutting to the next level using artificial intelligence (AI). The aim is to monitor cutting processes in real time, optimize them automatically and thus ensure consistently high quality.

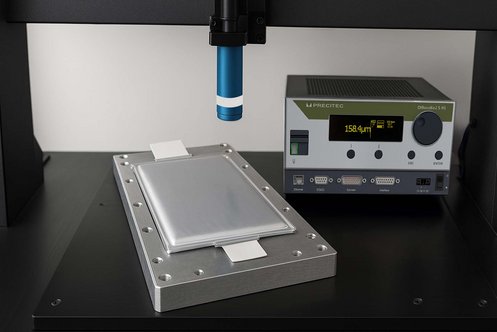

Intelligent sensor technology and machine learning enable process deviations to be detected precisely - with an accuracy of up to 97.9%. An FPGA-based computer with response times of just 1-2 milliseconds ensures genuine real-time capability. The method of minimally invasive laser modulation (MILM), with which small signals are specifically introduced into the cutting process in order to provide the AI with meaningful data for process analysis, is particularly exciting.

A demonstrator - a laser blanking system from Dreher Automation - will show how AI-supported process monitoring not only makes laser cutting more reliable, but also more efficient and flexible. For Precitec, DIPOOL is an important step towards autonomous laser machines that optimally meet the requirements of Industry 4.0.