Non-Contact 3D-Inspection of Turbine Blades

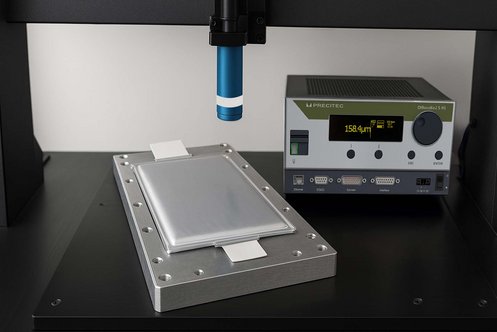

Watch this Video: The CLS line sensor is especially suitable for non-contact 3D inspection of turbine blades.

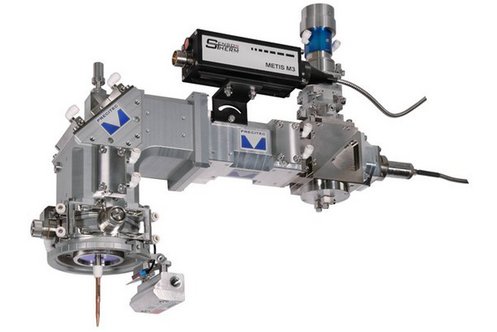

Because its optical probes can easily be exchanged, a wide bandwidth with respect to resolution, pixel size, number of measured Points, and duration of measurement can be achieved.

Showing the line scanner in use, the rapid exchange of optical probes between two measurements is demonstrated. This has influence on axial resolution, changing from 80 nm to 320 nm, as well as changes in pixel size.

See application video on"Youtube"