Intelligent seam inspection for top quality laser welding

SeamControl is the advanced sensor system for optical laser weld seam inspection - based on the proven technology of the SOUVIS system and consistently further developed to meet the requirements of modern, networked production environments. With the help of AI-supported image processing and high-resolution sensor technology, the system detects even the finest geometries - even on inclined or highly reflective surfaces. SeamControl provides both the visual surface and the precise height profile of the weld seam in real time, thus sustainably increasing quality assurance in laser welding.

As a stand-alone system, SeamControl works independently of the welding station and can be seamlessly integrated into existing production lines. It detects surface defects and seam deviations with high precision and evaluates them automatically using predefined tolerances. The smallest gaps, surface pores or geometry errors are reliably identified and classified - good parts remain in the process, bad parts are specifically ejected. The result: maximum process reliability with a minimum reject rate.

Intelligent fault detection with real-time data fusion

Seam inspection with AI support

SeamControl uses artificial intelligence to reliably detect defects such as joint misalignment, geometric deviations or pores - much more precisely than with conventional systems. The AI-based evaluation minimizes false evaluations, increases repeat accuracy and enables maximum detection rates - for maximum process reliability and quality.

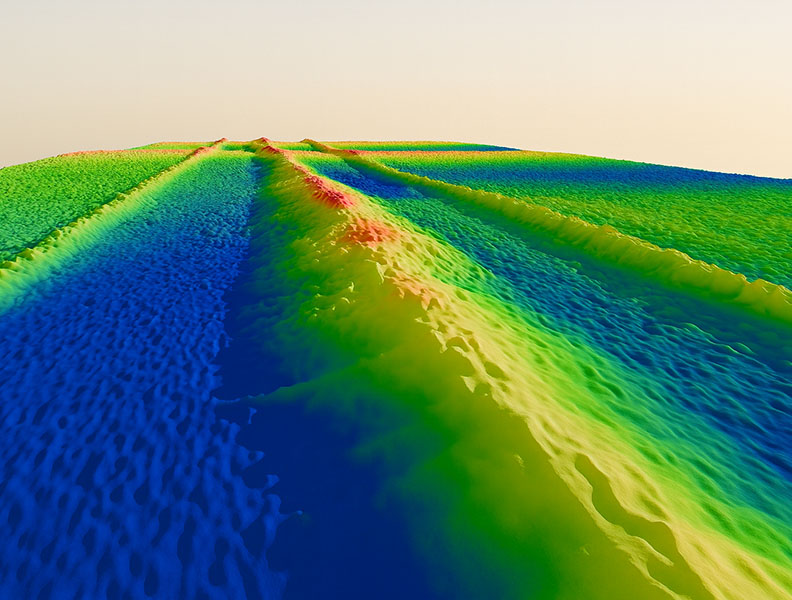

Gray image and 3D data fusion in real time

SeamControl combines structured 3D height profiles with gray image information - in real time and perfectly coordinated. The simultaneous evaluation of both data sources enables a much more precise analysis of the weld seam quality. This means that defects are reliably detected even in complex seam situations - on several levels simultaneously.

Optimized depth of field and resolution

The new generation of sensors in SeamControl delivers razor-sharp images, even with complex component geometries or reflective surfaces. Thanks to optimized depth of field, the seam remains in focus even with inclinations or height differences - for reliable analysis without compromising on quality.

What types of seams can typically be inspected?

Solder seams

SeamControl can be used to reliably inspect solder seams, such as those used in battery module and cell connector manufacturing. High-resolution quality monitoring ensures that stable and reproducible results are achieved even with fine seam structures and heat-sensitive materials.

Structural seams in safety-related applications

SeamControl is also suitable for downstream quality monitoring of structural seams, such as those used in automotive, bodywork, and mechanical engineering. Precise optical seam inspection after laser welding ensures the required strength and integrity of each welded joint and helps to identify rejects at an early stage.

Visible seams with high optical requirements

SeamControl can also be used to inspect visible seams in high resolution after the welding process, for example in household appliances, white goods, or design components. Camera-based quality inspection of welded and soldered seams ensures consistently high optical and functional quality.

Technical data

- Typical seam widths: Detection of weld and solder seam widths in the range from approx. 0.5 mm to 15 mm, depending on the variant / application

- Measurement of height differences: Precise detection of height variations of up to 17 mm, even with reflective or complex surfaces

- Defect detection at high speed: Thanks to an image frequency of up to 8 kHz, SeamControl reliably detects even small defects (e.g. surface pores or misalignment from approx. 100 µm) - even in fast processes with several meters per minute

- Flexible integration: Can be seamlessly connected to existing systems via the WeldMaster fieldbus interface

We need your consent to load the form!

We use Marketing Cloud Account Engagement (Pardot) Forms to embed content that may collect data about your activity. Please review the details and click in the Pardot box to accept the service and see the content. If the form is not displayed correctly, please click once more on Download the data sheet now.

Do you still have any questions or would you like an offer? Then contact us!