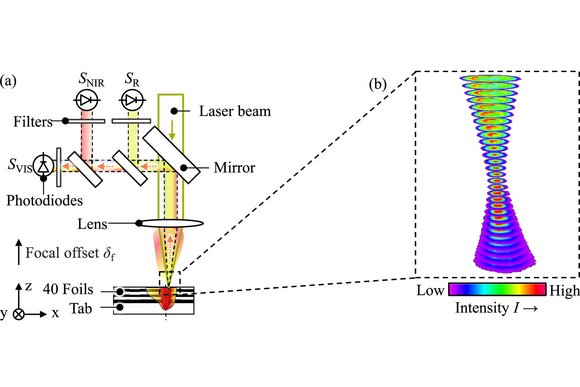

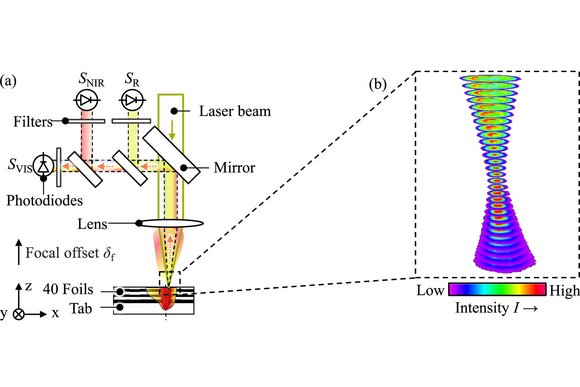

Monitoring laser beam welding process of cell-internal contacts in lithium-ion batteries

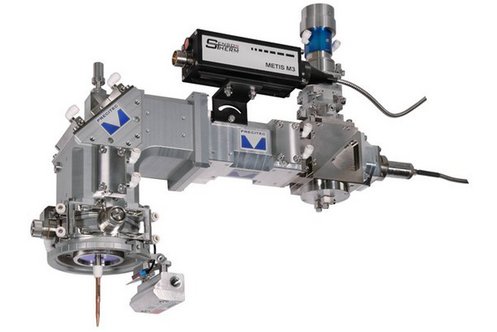

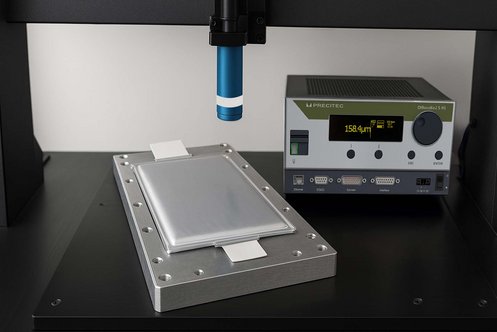

A major challenge in producing lithium-ion battery cells is establishing reliable and stable manufacturing processes. Cell-internal contacting is one step in the battery cell production chain in which the uncoated sections of the current collector foils of the individual electrodes in the cell stack are electrically connected by a joining process. Laser-welding technologies open up new possibilities for improving the battery cell design. However, the industrial use of laser beam welding for cell-internal contacting has so far been limited. Numerous process parameters influence the quality of the resulting welds, necessitating the need for seam quality monitoring. Currently, weld inspection is performed offline and mainly manually, making the evaluation highly dependent on individual inspectors. Implementing inline process monitoring has the potential to reduce time-consuming quality checks after the joining process and to increase the objectivity of the seam evaluation.

Lesen Sie die Pressemitteilung (in Englisch)