Process monitoring in laser welding

Technologies and systems for precise inline quality monitoring

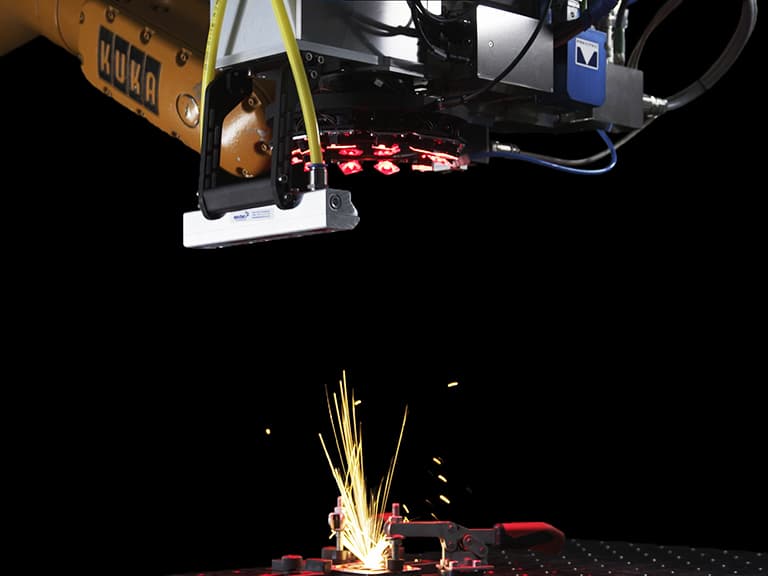

Process monitoring in laser welding is a key component of quality control in industrial manufacturing. Precitec systems capture process-relevant signals inline and enable seamless monitoring of weld seam quality. In series production, this form of inline monitoring determines process stability, efficiency, and reproducible welding results.

In series production, process monitoring determines quality and efficiency. Precitec offers a wide range of inline and offline systems that measure seam position, gap dimensions, molten pool, and weld depth in real time. Deviations are detected immediately, scrap is reduced, and the quality of each weld seam is fully documented.

Thanks to adaptive gap bridging, material diversity, and automatic data storage, our systems meet the highest standards—whether in e-mobility, car body construction, or medical technology. Optimized for 24/7 use, they integrate seamlessly into existing production lines and ensure consistently precise results.

Process monitoring for series production – from classic to AI-supported

- Monitoring of quality fluctuations

- Increasing the output

- 100% traceability and transparency

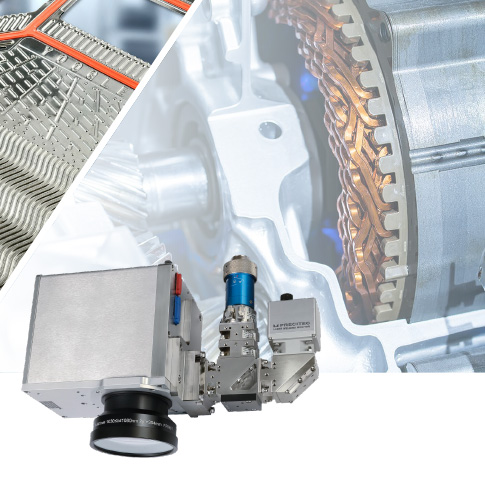

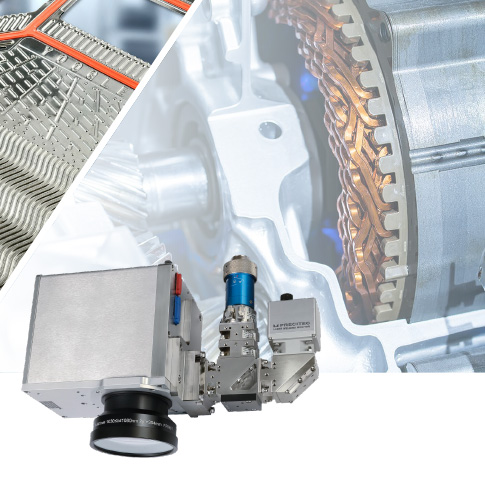

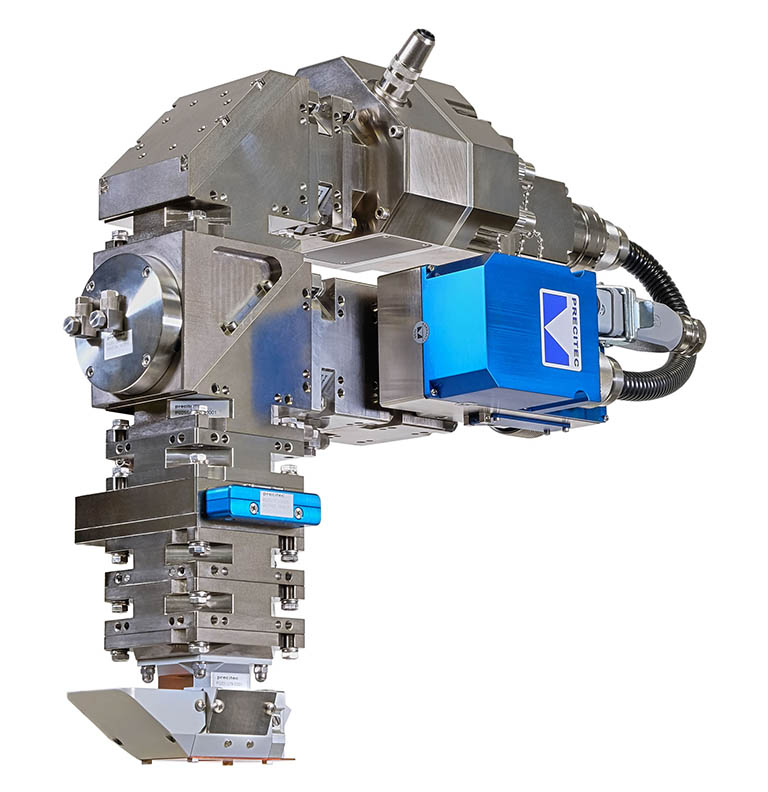

Sophisticated laser welding processes with filler wire

- Camera-based seam tracking with AI support

- Adaptive gap bridging

- Ideal for 24/7 operation

- Full transparency thanks to data interface

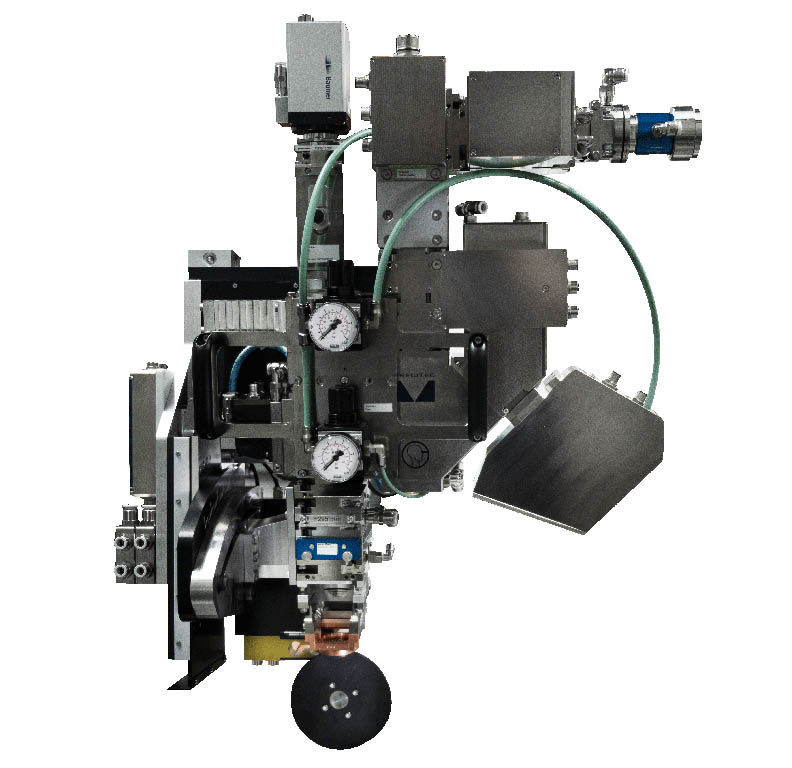

Automated complete solution for laser welding of roof seams

Creation of tight, high-quality weld seams

with controlled pressure wheel for a constant contact pressure

Optimizes overlap and fillet weld joints

Automated total solution for your welding process

- Tracking of the seam, beam guidance and shaping as well as online quality control

- Optimal for 24/7 operation

- 100 % documentation and networking

Monitoring and control of your welding depth

- Highly accurate measurement in real time

- Avoidance of rework and rejects

- 100 % documentation, transparency, and traceability

Optical inspection of laser welds with AI

- Highly accurate 3D & grayscale fusion in real time

- Maximum detection rates when inspecting soldered, visible, and structural welds

- Optimized depth of field even with complex component geometries or reflective surfaces

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/Home/laser-welding/Koepfe_Ressource_768x576_01.jpg)