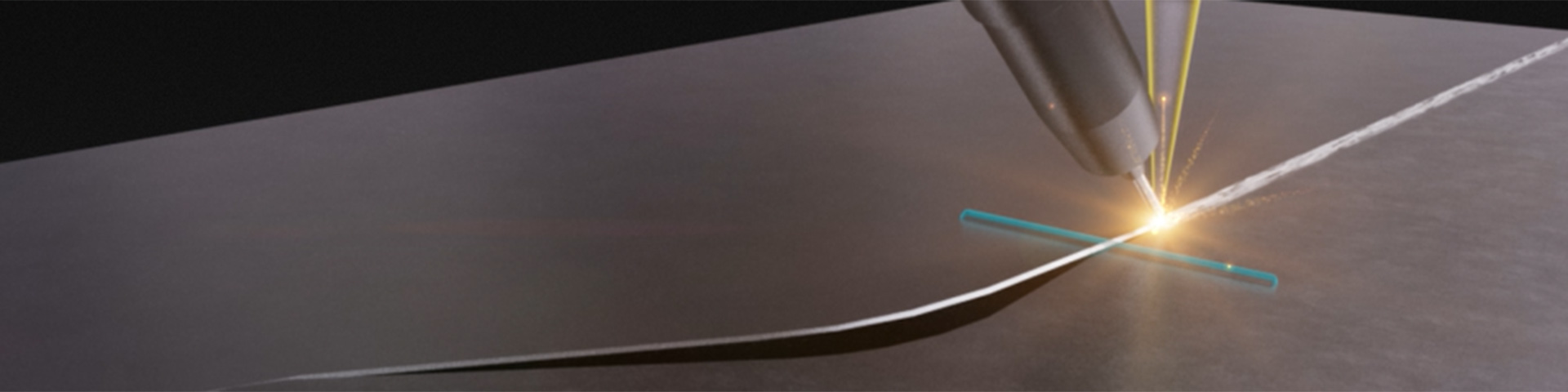

Intelligent laser welding with filler wire

WeldMaster Wire Select - Contactless. Adaptive. Efficient.

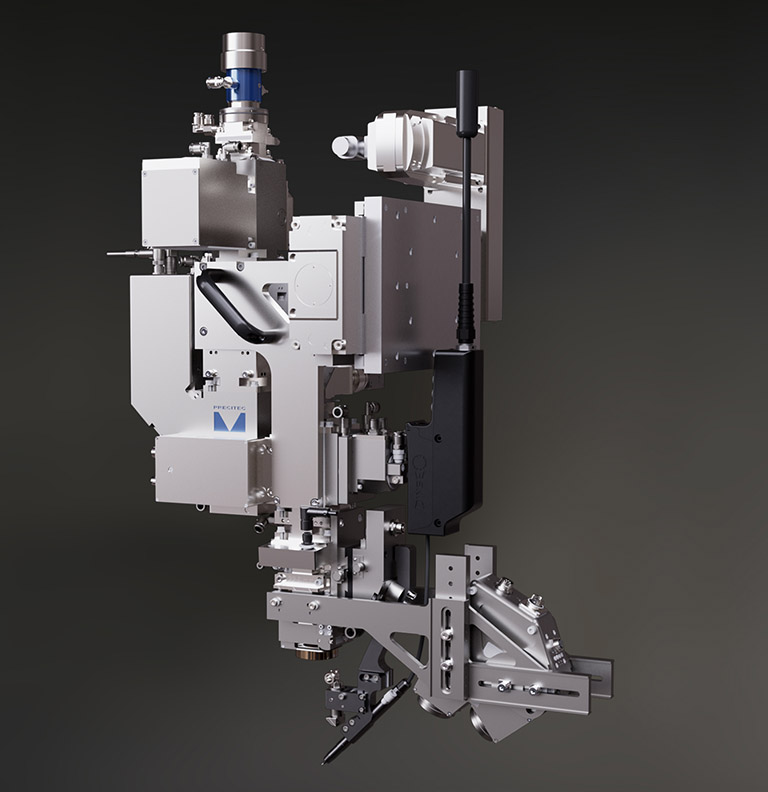

The WeldMaster Wire Select is the innovative solution for camera-based laser welding and laser soldering with filler wire. The system combines welding optics, optical seam tracking and integrated quality control to create a high-precision complete system for automated series production.

Unlike tactile methods, optical seam guidance with a camera enables wear-free, fast, and flexible process control without mechanical sensors or special seam preparation - even with zero gap.

The following animation demonstrates camera-based seam tracking.

Flexible joining - without time-consuming seam preparation

Camera-based seam tracking with AI support

In contrast to tactile processes, the WeldMaster Wire Select does not require any special seam preparation for the cored wire along the geometry. The AI-supported WeldMaster software automatically recognizes common joining geometries and regulates the wire feed based on the gap volume.

Adaptive gap bridging

A direct calculation of the slit volume enables precise wire dosing. In addition, the laser power, focus position and power modulation are dynamically adjusted.

Highest process speed

Process speeds of more than 6 m/min can be achieved thanks to the optical pre-positioning in the feed. Gap changes due to component tolerances or heat input are compensated on-the-fly - for consistent, high-quality weld seams.

WeldMaster Wire Select - your advantages at a glance

Rely on an adaptive, precise and fully integrated system for demanding laser welding processes with filler wire. With state-of-the-art camera technology, AI-supported seam tracking and seamless integration into digital production environments, you can achieve reproducible results at the highest quality level - economically, transparently and reliably.

Technological highlights in detail

- Adaptive gap bridging - direct control, control of process parameters

- Adaptive wire control based on the gap geometry

- Control of laser power and focus position

- Laser power distribution and adaptive laser power modulation based on the geometry data

- Compensation of component tolerances with the aid of focus position control

- Optional control of the seam upper bead (3D measurement)

Maximum flexibility for laser welding in the automotive industry

The WeldMaster Wire Select is the innovative solution for precise, adaptive laser welding – developed for the most demanding requirements in automotive manufacturing. Whether battery cases, hang-on parts, or body-in-white assemblies: the system combines intelligent process control with flexible filler wire feed, ensuring consistently high weld seam quality – even with large component tolerances or complex geometries.

Laser welding of battery cases for electric vehicles

The WeldMaster Wire Select is the optimal solution for laser welding battery cases – one of the most demanding applications in electromobility. The cases are typically made of high-strength aluminum alloys of the 5xxx and 6xxx series, whose crack- and warp-prone properties require a precisely controlled welding process. This is precisely where a high-precision, adaptive welding process is required that works reliably – without time-consuming seam preparation and remains consistently process-reliable even with component tolerances.

Typical applications include cell carriers, cooling plates, module housings, and cross members—key components of battery architecture. The WeldMaster Wire Select not only reduces scrap and rework in these applications, but also offers a future-proof solution thanks to its intelligent process control – even for upcoming battery generations with more complex geometries and thinner wall thicknesses.

The advantages at a glance:

- No seam preparation necessary – even with component tolerances or poorly milled edges

- Adaptive gap bridging through automatic adjustment of wire feed, laser power, and position in real time

- Optical, non-contact seam tracking – precise and reliable, even with warped components

- Robust against manufacturing tolerances – ideal for large series production with high throughput

- Optional integrated seam inspection (LWM or triangulation)

Laser welding of hang-on parts – with and without filler wire

In automotive manufacturing, hang-on parts such as doors, flaps, fenders, and other attachments are among the components with the highest requirements in terms of cycle time, geometric diversity, and variant flexibility. Different materials and varying gap dimensions require a solution that can be flexibly adapted to any component situation without manual adjustment.

The WeldMaster Wire Select expands the proven WeldMaster Scan&Track platform with the ability to automatically feed filler wire – without compromising existing functions. This means that the full Scan&Track functionality with intelligent, optical process control remains completely intact.

The combination of adaptive seam tracking and situation-dependent wire feed offers additional flexibility for complex manufacturing processes. Especially in cases with large gaps, seams that are difficult to detect optically, or material-related requirements for filler material, Wire Select ensures a reliable connection – with consistently high quality and productivity.

Thanks to this seamless integration, WeldMaster Wire Select is not a competing system to the existing WeldMaster, but a powerful extension for even more applications – especially where remote welding without filler wire reaches its physical limits.

The advantages at a glance:

- Full WeldMaster Scan&Track functionality with additional wire feed if required

- Real-time optical seam search – automatically detects the component position without mechanical contact

- Intelligent gap detection with dynamic adjustment of the weld track for each component variant

- Automatic wire feed for wide gaps or poor optical seam detection

- Maintenance-free and durable – no wear due to mechanical probes

- Ideal for variant production and flexible lines – no changeover times when changing components

Body-in-white: Car body welding with maximum flexibility

In car body manufacturing (body-in-white), precision, speed, and repeatability are essential – especially for complex assemblies made of steel, aluminum, or mixed materials. The WeldMaster Wire Select was developed precisely for these requirements and impresses with its intelligent adaptability and easy integration.

Typical applications include welding A- and B-pillars, cross members, door frames, and sills, as well as joining outer skin and structural parts. The system also meets the highest requirements for visible seam quality and crash safety – exactly in line with OEM specifications.

The advantages at a glance:

- Real-time seam tracking – reliable on all common materials and surfaces

- Flexible welding parameters for a wide variety of materials and seam geometries

- Automatic gap bridging – stable process even with warped components or changing tolerances

- Easy integration into existing robot cells and production lines

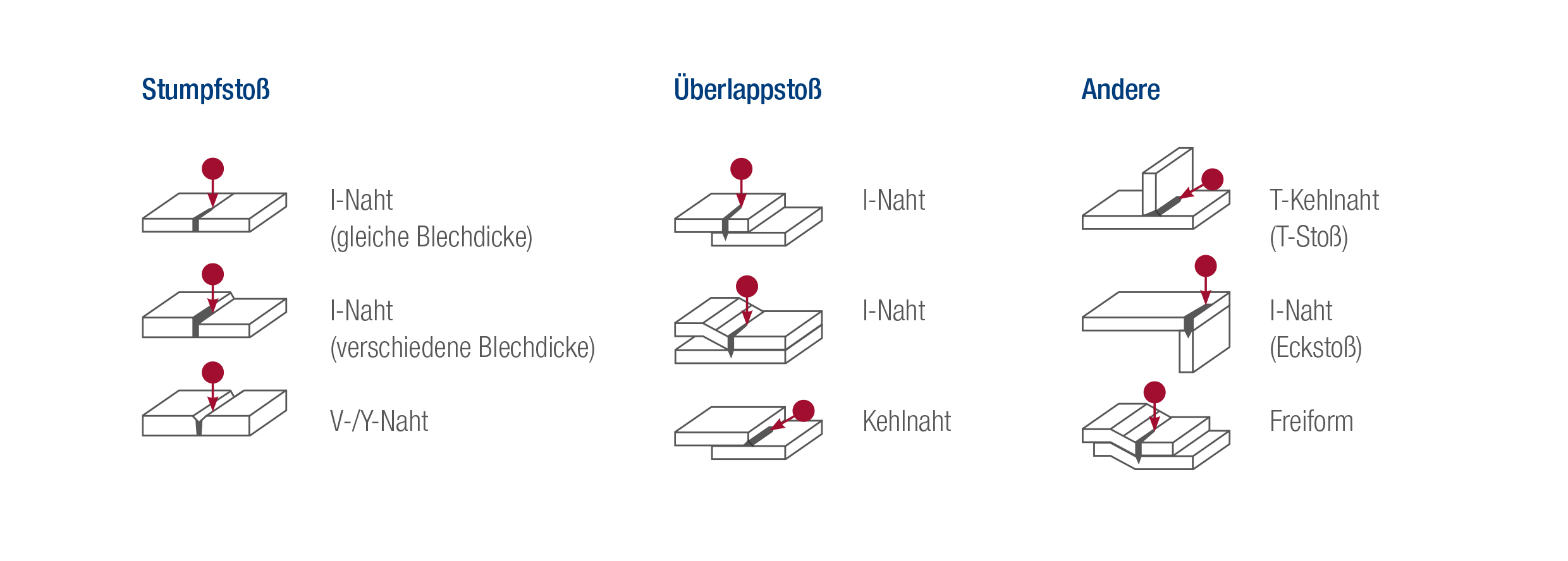

Typical seam geometries and areas of application

- E-mobility (battery housings/battery boxes, seal welds)

- Zero-gap and fillet welds for aluminum alloys

- Car body construction

- Stainless steel applications

- Welding on the fly

Technical data

- Wavelength: 1010 - 1120 nm

- Laser power: up to 12 kW (CW), higher laser power on request

- Pre-running triangulation line: 50 mm

- Interfaces (fieldbus): Profinet, EtherCAT, Ethernet/IP

- Laser welding and laser soldering with filler wire

We need your consent to load the form!

We use Marketing Cloud Account Engagement (Pardot) Forms to embed content that may collect data about your activity. Please review the details and click in the Pardot box to accept the service and see the content. If the form is not displayed correctly, please click once more on Download the data sheet now.

Do you still have any questions or would you like an offer? Then contact us!